Small bag horizontal packaging machine

This equipment is mainly developed and designed for the filling and packaging of powder materials and small particle materials. It is widely used in fine chemicals, lithium batteries, rare earths, ceramics, plastic particles and other powder materials, and is suitable for filling and packaging small bags weighing 10-50KG.

Classification:

Product

Keywords:

Small bag horizontal packaging machine

Description

Description

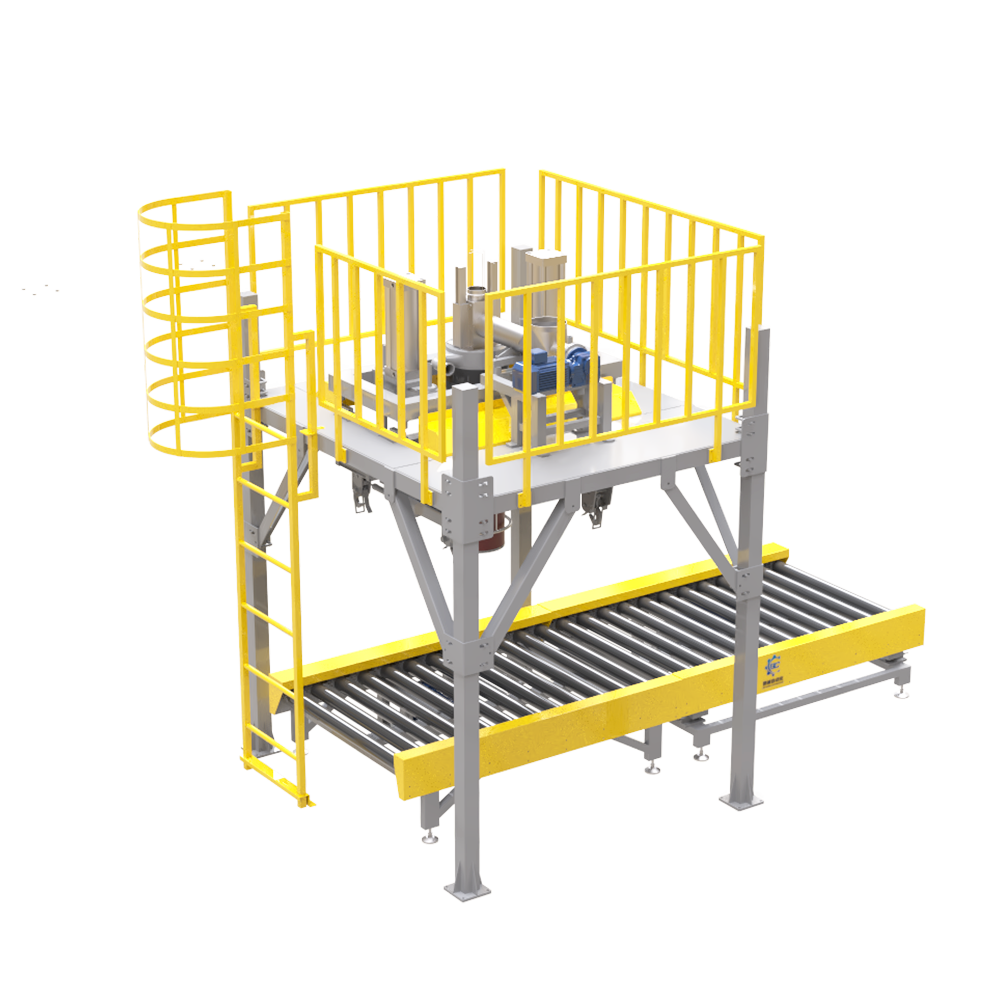

(1) This equipment is mainly developed and designed for the filling and packaging of powder materials and small particle materials. It is widely used in fine chemicals, lithium batteries, rare earths, ceramics, plastic particles and other powder materials, and is suitable for filling and packaging small bags weighing 10-50KG.

(2) The filling process adopts the feeding method of two horizontal screws of different sizes, with multi-stage variable frequency control to ensure both speed and accuracy.

(3) The bag clamp adopts a pneumatic clamping structure, which has high efficiency and good sealing effect.

(4) Install vibration or fluidization devices such as arch breaking devices in the transition bin to prevent material bridging.

(5) Dust hood (The dust hood of this equipment has an interface for docking with the dust removal equipment, as long as it is connected to the dust removal equipment. Note: The dust removal equipment needs to be purchased separately and is not included in this equipment!).

(6) The overall bag clamping and conveying mechanism is equipped with a weighing and measuring system, which measures and fills according to the pre-set weight.

(7) The material pipeline structure of this device is simple, which is very suitable for frequent cleaning or material replacement requirements.

(8) Independent electrical cabinet, touch screen operation, PLC control.

(9) Conveying method: 1. USU304 unpowered drum, 2. PVC belt conveyor (choose according to demand).

Technical parameters

(1) Filling method: Horizontal spiral feeding

(2) Filling weight: 10-50KG (according to packaging material specifications)

(3) Filling accuracy: ± ≤ 0.1%

(4) Filling speed: ≥ 2-4 bao/h

(5) Suitable containers: open pockets, cardboard boxes, buckets

(6) Power supply: 3P AC208-415V 50/60Hz

(7) Whole machine power: 1.5KW

(8) Air pressure: 0.4-0.8mpa

(9) Gas consumption:<3m³/h

Main configuration list

| Serial Number | Name | Brand |

| 1 | Gear Reduction Motor | Jingyan |

| 2 | Worm Gear Reduction Motor | Sailan |

| 3 | Variable Frequency Drive (VFD) | Inovance/Delta |

| 4 | Load Cell | Mettler Toledo |

| 5 | Photoelectric Sensor | Omron |

| 6 | Low-Voltage Electrical Apparatus | Schneider |

| 7 | Intermediate Relay | IDEC (Japan)/Schneider |

| 8 | Pneumatic Components | Airtac |

| 9 | Bearing | NSK |

| 10 | Oil Seal | NAK |

| 11 | Control System | Inovance |

| 12 | Touch Screen | Kunlun Tongtai/Inovance |

Previous Page

Next Page

Previous Page

Next Page