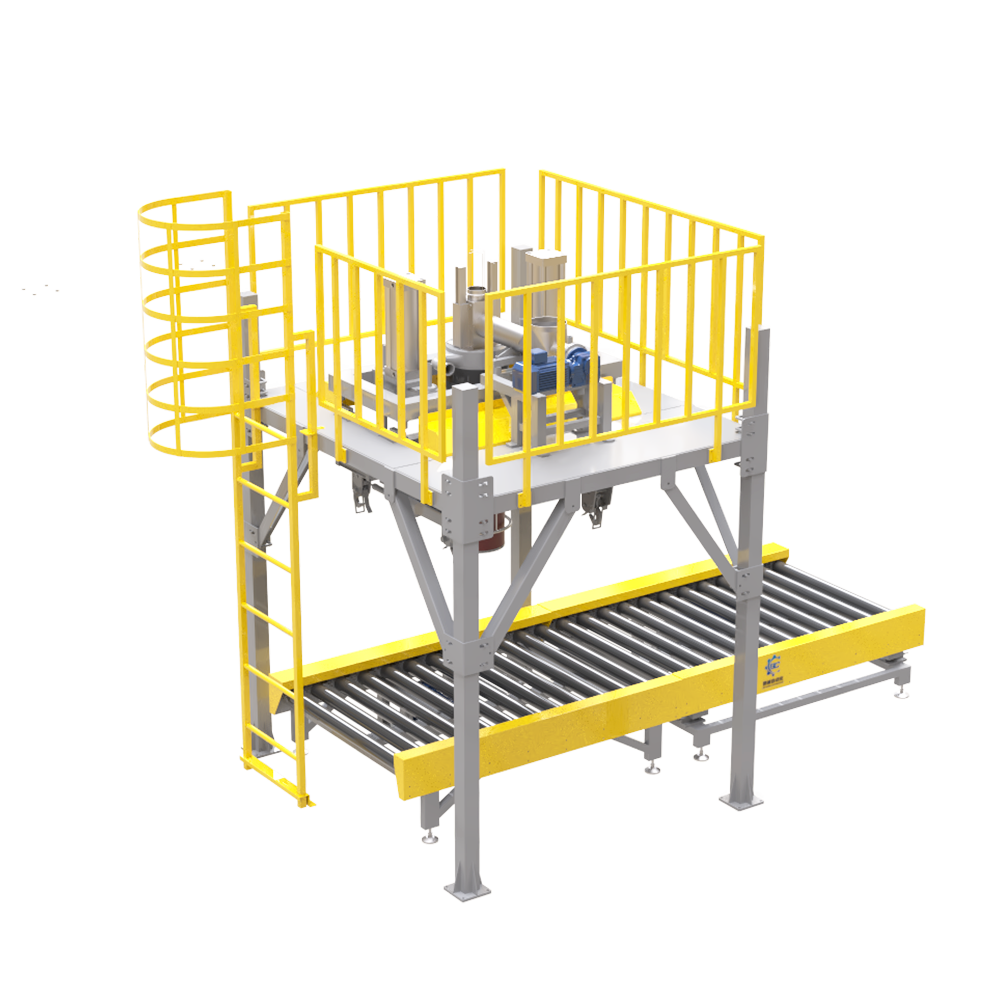

Small bag degassing packaging machine

This equipment is mainly designed for filling and loading ultrafine powders and powder materials with high gas content. It is widely used in fine chemicals, lithium graphite, lithium iron phosphate, carbon powder, activated carbon powder and other powder materials with high gas content and good flowability. It is suitable for small bag filling and packaging of 10-50KG.

Classification:

Product

Keywords:

Small bag degassing packaging machine

Description

Describe

● This equipment is mainly designed for filling and loading ultrafine powders and powder materials with high gas content. It is widely used in fine chemicals, lithium graphite, lithium iron phosphate, carbon powder, activated carbon powder and other powder materials with high gas content and good flowability. It is suitable for small bag filling and packaging of 10-50KG.

● The combination of vertical filling screw and vacuum degassing material tube mechanism (the screw pushes and squeezes the material, and the vacuum degassing material tube is responsible for vacuuming and degassing the material during the screw pushing and squeezing process), the vacuum degree of the degassing system can be adjusted according to the actual characteristics of the material to ensure the best vacuum degree for exhaust and loading.

● The filling screw is controlled by a servo motor to achieve multi-stage speed filling and feeding, thereby achieving fast loading and precise measurement control and weighing accuracy during the loading process.

● Positive pressure blowback filter system: Its main function is to blow through the material attached to the filter mesh, maintaining the smoothness of the filter. The positive pressure blowback pressure and time can be adjusted, and can be adjusted according to the characteristics of the material.

● The overall bag clamping and conveying mechanism are equipped with weighing sensors, which perform multi-stage speed filling according to the pre-set weight.

● Bottom filling method is used for filling, with lifting and lowering to control material drop and reduce dust.

● The overall lifting mechanism is driven and controlled by a servo motor, and the lifting speed can be set arbitrarily.

● Design a mixing arch breaking device in the mixing transition chamber to prevent material bridging.

● Independent electrical cabinet, touch screen operation, PLC control.

● The conveying adopts PVC belt transmission or non powered drum transmission.

Equipment parameters

● Filling method: Vertical spiral feeding

● Degassing method: vacuum negative pressure+physical extrusion

● Filling weight: 10-50KG (according to bag specifications)

● Filling accuracy: ± ≤ 0.1%

● Filling speed: ≥ 1-2 bao/min

● Suitable container: open pocket Paper box cylinder

● Power supply: 3P AC208-415V 50/60Hz

● Overall power: 5.6KW

● Air pressure: 0.4-0.8mpa

● Gas consumption:<3m ³/h

Main configuration

| Serial Number | Name | Brand |

| 1 | Geared Motor | Jingyan |

| 2 | Servo Motor | Inovance/Delta |

| 3 | Worm Gear Motor | Sailan |

| 4 | Frequency Converter | Inovance/Delta |

| 5 | Load Cell | Mettler Toledo |

| 6 | Photoelectric Sensor | Omron |

| 7 | Low Voltage Electrical Appliance | Schneider |

| 8 | Intermediate Relay | Japan IDEC/Schneider |

| 9 | Pneumatic Components | Airtac |

| 10 | Bearing | NSK |

| 11 | Oil Seal | NAK |

| 12 | Control System | Inovance |

| 13 | Touch Screen | Kunlun Tech/Inovance |

Previous Page

Next Page

Previous Page

Next Page