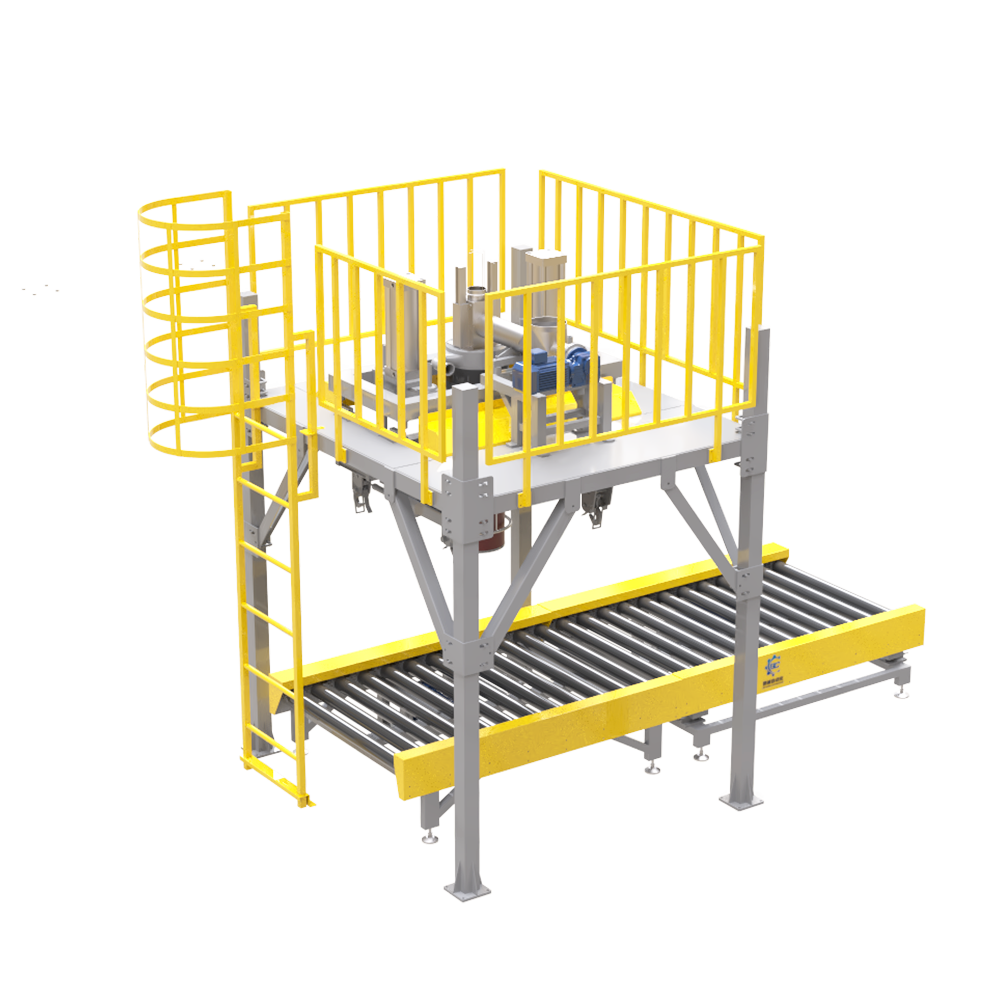

Degassing ton bag packaging machine

This equipment is mainly designed for filling and loading ultrafine powders and powder materials with high gas content. It is widely used in fine chemicals, lithium graphite, lithium iron phosphate, carbon powder, activated carbon powder and other powder materials with high gas content and good flowability. It is suitable for filling and packaging bags weighing 100-1000KG.

Classification:

Product

Keywords:

Degassing ton bag packaging machine

Description

Description and Characteristics

● This equipment is mainly designed for filling and loading ultrafine powders and powder materials with high gas content. It is widely used in fine chemicals, lithium graphite, lithium iron phosphate, carbon powder, activated carbon powder and other powder materials with high gas content and good flowability. It is suitable for filling and packaging bags weighing 100-1000KG.

● The combination of vertical filling screw and vacuum degassing material tube mechanism (the screw pushes and squeezes the material, and the vacuum degassing material tube is responsible for vacuuming and degassing the material during the screw pushing and squeezing process), the vacuum degree of the degassing system can be adjusted according to the actual characteristics of the material to ensure the best vacuum degree for exhaust and loading.

● The filling screw is controlled by a servo motor to achieve multi-stage speed filling and feeding, thereby achieving fast loading and precise measurement control and weighing accuracy during the loading process.

● Positive pressure blowback filter system: Its main function is to blow through the material attached to the filter mesh, maintaining the smoothness of the filter. The positive pressure blowback pressure and time can be adjusted, and can be adjusted according to the characteristics of the material.

● The bag clamp adopts an inflatable card bag with excellent sealing effect.

● The design has a quick bag expansion function to reduce wrinkles in empty bags before filling.

● The design has an automatic bag stamping function, which can be freely adjusted according to the on-site usage situation to ensure the flatness and firmness of the material.

● A weighing and measuring system is equipped above the overall bag clamping and lifting mechanism to measure and fill according to the pre-set weight.

● Independent electrical cabinet, touch screen operation, PLC control.

● The conveyor adopts 304 stainless steel drum and double row chain transmission method.

Technical parameters

● Filling method: Horizontal spiral feeding

● Filling weight: 100-1000KG

● Filling accuracy: ± ≤ 0.1%

● Filling speed: 6-10bao/h

● Suitable container: ton bag

● Power supply: 3P AC208-415V 50/60Hz

● Whole machine power: 3.9KW (including one section of drum conveyor)

● Air pressure: 0.4-0.8mpa

● Gas consumption: 3m³/h

Main configuration list

| Serial Number | Name | Brand |

| 1 | Gear Reduction Motor | Jingyan |

| 2 | Servo Motor | Inovance/Delta |

| 3 | Worm Gear Reduction Motor | Sailan |

| 4 | Variable Frequency Drive (VFD) | Inovance/Delta |

| 5 | Load Cell | Mettler Toledo |

| 6 | Photoelectric Sensor | Omron |

| 7 | Low-Voltage Electrical Apparatus | Schneider |

| 8 | Intermediate Relay | IDEC (Japan)/Schneider |

| 9 | Pneumatic Components | Airtac |

| 10 | Bearing | NSK |

| 11 | Oil Seal | NAK |

| 12 | Control System | Inovance |

| 13 | Touch Screen | Kunlun Tongtai/Inovance |

Previous Page

Next Page

Previous Page

Next Page